NAPIPM 2018 Event: Transforming Supply Chains

The (NAPIPM) National Association of Public Procurement and Inventory Management. held its annual conference in 2018, bringing together professionals from diverse industries. This event is a crucial gathering for those involved in supply chain management, procurement, and inventory management. The conference focused on key challenges and trends shaping supply chain practices.

At NAPIPM 2018, innovation took center stage, especially in technology-driven solutions. Attendees explored the latest trends, including artificial intelligence, blockchain, and the Internet of Things (IoT), all of which are transforming supply chains worldwide. These technologies are now essential for achieving greater efficiency and transparency in supply chain processes.

Another prominent theme was resilience. In today’s global economy, supply chains face constant disruptions, from natural disasters to trade uncertainties. NAPIPM 2018 emphasized the importance of building resilient supply chains that can quickly adapt to such challenges. Experts at the conference shared strategies for enhancing flexibility and preparing for unexpected events.

Sustainability and ethical sourcing were also highlighted throughout the conference. Organizations are increasingly aware of their environmental impact, and many are choosing greener, more ethical supply chain practices. This shift reflects the growing importance of responsible sourcing and sustainable logistics in the industry.

Overall, the goal of NAPIPM 2018 was to equip supply chain managers with insights and tools for modern challenges. This blog post provides a recap of the event, covering the key trends, strategies, and innovations discussed. Readers will gain a clear understanding of the essential takeaways from NAPIPM 2018, as well as actionable insights to enhance their own supply chain practices.

| Aspect | Key Facts | Figures / Examples |

|---|

| Event | NAPIPM 2018 Annual Conference | Gathered supply chain professionals from diverse industries |

| Focus Areas | Innovation, Resilience, Sustainability, Technology | AI, Blockchain, IoT, and Supply Chain Resilience |

| Innovation Focus | Technology-driven solutions | AI, Blockchain, IoT for supply chain improvements |

| Resilience in Supply Chains | Importance of adaptability and flexibility to disruptions | Examples: Natural disasters, trade uncertainties |

| Sustainability & Ethical Sourcing | Increasing focus on environmentally conscious and ethical supply chain practices | Adoption of greener, sustainable logistics practices |

| Collaboration with Suppliers | Building open communication and transparency with suppliers to enhance resilience | Use of digital platforms for real-time updates |

| Inventory Optimization | Role of forecasting tools and AI in balancing supply and demand | AI-powered forecasting, Just-in-Time inventory practices |

| Risk Assessment & Contingency Plans | Proactive risk identification and development of contingency plans | Strategies: Alternative suppliers, flexible sourcing |

| Automation in Supply Chains | Use of automation to reduce human error and optimize operations | Automated inventory management, Robotic Process Automation (RPA) for repetitive tasks |

| AI in Supply Chain Management | Data-driven decision-making for improved demand forecasting and route optimization | Predictive analytics, Route optimization |

| Blockchain | Provides transparency, traceability, and secure transactions in the supply chain | Blockchain for supply chain tracking and security |

| IoT in Supply Chain | Real-time visibility of shipments, inventory, and assets through IoT devices | Shipment tracking, warehouse monitoring for better resource planning |

| Robotics in Warehousing | Automation of repetitive tasks in warehousing for faster processing | Automated picking systems, sorting, and packing automation |

| Best Practices for Implementing Technology | Assess needs, select compatible solutions, and ensure employee training | Identifying key areas for improvement, ensuring readiness for change |

| Security & Compliance | Need for cybersecurity measures and regulatory compliance when integrating new technologies | Encryption, access controls, and ensuring compliance with local/international regulations |

| Impact Tracking | Monitor technology impact with KPIs and adjust strategies based on data | Order accuracy, cost savings, and technology optimization |

| Key Takeaways from NAPIPM 2018 | Technology adoption, resilience, supply chain collaboration, sustainability, and risk management | AI, IoT, blockchain in enhancing supply chain efficiency and transparency |

Key Trends in Supply Chain Management

Resilience and Efficiency through Supplier Collaboration

Building collaborative relationships with suppliers is essential for strengthening supply chains. Discussions highlighted the value of open communication and transparency with suppliers to enhance mutual responsiveness and resilience. Companies were encouraged to work closely with suppliers, aligning goals to meet changing demands quickly.

- Enhanced Communication Tools: New digital platforms enable real-time updates and help manage orders, track shipments, and solve issues faster. This reduces delays and promotes smooth collaboration between businesses and suppliers.

- Trust and Transparency: Transparency in data-sharing strengthens trust among supply chain partners. Open communication helps prevent misunderstandings and supports better coordination during disruptions.

Inventory Optimization and Demand Forecasting

Efficient inventory management helps balance costs and meet customer demands effectively. The event emphasized the role of optimization and forecasting tools, which analyze historical data to anticipate demand trends. Companies can adjust their inventory based on these insights, reducing overstocking and stockouts.

- AI-Powered Forecasting: Artificial intelligence is transforming forecasting with predictive analytics, which uses past data to predict future trends. This allows businesses to plan inventory better, minimizing unnecessary stock levels and associated costs.

- Just-in-Time (JIT) Inventory: JIT inventory practices minimize excess stock and associated storage costs. The event discussed how JIT helps streamline cash flow and minimize waste by ensuring stock availability aligns with demand.

Risk Assessment and Contingency Planning

Risk assessment is a proactive approach to minimize potential supply chain disruptions. Attendees discussed how identifying and preparing for potential risks can help companies mitigate disruption and maintain operational stability.

- Identifying Key Risks: Risk assessment includes evaluating potential disruptions such as natural disasters, supplier issues, or market fluctuations. By identifying these early, businesses can establish safeguards to minimize impacts.

- Developing Contingency Plans: Effective contingency plans help companies maintain operations despite disruptions. Experts shared examples of strategies like alternative suppliers and flexible sourcing to keep processes running smoothly under unexpected circumstances.

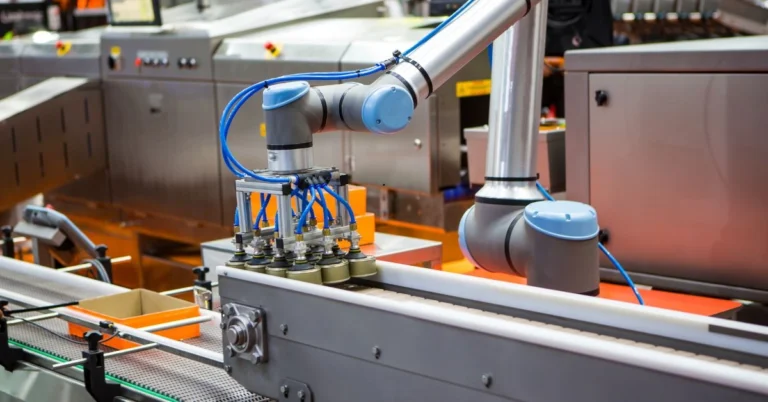

Automation as a Driver of Efficiency

Automation in supply chain processes streamlines operations and reduces human error. Automation was emphasized as a solution for optimizing repetitive tasks, saving time, and allowing employees to focus on more complex tasks.

- Automated Inventory Management: Tools such as barcode scanners and automated tracking systems simplify inventory management, allowing real-time updates and reducing manual work. These systems support timely insights into inventory needs and potential supply issues.

- Robotic Process Automation (RPA): RPA supports the automation of routine tasks like data entry and order processing, freeing up staff for higher-level responsibilities. This results in faster processing, improved accuracy, and better use of resources.

Innovative Technologies Shaping the Supply Chain

Artificial Intelligence (AI) for Intelligent Supply Chain Management

AI is transforming supply chain management through data-driven decision-making. AI solutions are optimizing demand forecasts, inventory management, and even route planning to help businesses operate more efficiently.

- Predictive Analytics: AI-powered predictive analytics enhance demand forecasting by analyzing historical data and market trends. This insight helps businesses better predict demand patterns, reducing overstock and stock shortages.

- Route Optimization: By analyzing factors such as traffic patterns and delivery windows, AI can identify the most efficient routes for shipments. This reduces delivery times, fuel costs, and the overall environmental impact of logistics.

Blockchain for Secure and Transparent Transactions

Blockchain technology provides transparency and traceability across supply chains. Event attendees discussed how blockchain creates a secure, immutable record of each transaction, which can strengthen trust with both suppliers and customers.

- Supply Chain Tracking: Blockchain technology provides a clear, traceable record of each step, which is especially useful for ensuring product authenticity and ethical sourcing.

- Enhanced Security: Blockchain prevents unauthorized alterations to supply chain records, reducing fraud risks. This technology reassures customers and suppliers of the integrity of each transaction.

Internet of Things (IoT) for Real-Time Supply Chain Visibility

IoT enhances supply chains by providing real-time data on inventory, shipments, and assets. IoT devices enable companies to track and manage resources more effectively, from warehousing to final delivery.

- Shipment Tracking: IoT devices track shipments and provide data on location and condition, allowing companies to respond to issues and delays proactively.

- Warehouse Management: IoT technology monitors stock levels in warehouses, providing real-time data for better resource planning. This allows managers to optimize operations and maintain ideal stock levels.

Robotics and Automation in Warehousing

Robotics and automation are transforming warehousing operations, enabling faster processing and greater accuracy. Robotic systems handle repetitive tasks, allowing workers to focus on more strategic tasks and reducing order fulfillment times.

- Automated Picking Systems: Robotic picking systems speed up the order-picking process and reduce errors. This boosts efficiency and helps companies meet customer demands more effectively.

- Sorting and Packing Automation: Automation in sorting and packing minimizes manual labor while enhancing accuracy. This results in shorter processing times and greater overall warehouse efficiency.

Best Practices for Implementing Supply Chain Technology

Assessing Needs and Readiness for Change

Before adopting new technologies, companies must assess their specific needs to ensure they invest in tools that align with their goals. This step prevents misalignment and ensures that technology investments bring tangible benefits.

- Identify Key Areas for Improvement: Focusing on specific needs, such as inventory management or order fulfillment, helps companies prioritize the most impactful technology investments.

- Evaluate Readiness for Change: Companies should assess their budget, resources, and workforce readiness to ensure a smooth transition to new technologies.

Selecting the Right Solutions

Choosing the right technology solutions is critical for successful implementation. Attendees discussed evaluating technology based on compatibility with existing systems, scalability, and ease of use.

- Compatibility with Existing Systems: Technologies should integrate seamlessly with current software and hardware to avoid technical issues.

- Scalability for Future Growth: Scalable solutions allow businesses to grow without major overhauls, ensuring technology investments remain valuable over time.

Training and Supporting Employees

Effective training and support are essential for a smooth transition to new systems. Well-prepared employees are more comfortable and productive with new technology.

- Comprehensive Training Programs: Training should cover all aspects of the new tools, including troubleshooting. Proper training reduces user errors and ensures faster adoption.

- Continuous Support and Feedback: Ongoing support and feedback channels help employees adjust over time, allowing companies to address issues promptly and optimize technology use.

Monitoring Technology Impact

Once implemented, companies should track the effectiveness of new technologies using key performance indicators (KPIs). Monitoring allows for adjustments and improvements based on real-time data.

- Setting KPIs: Clear metrics, such as order accuracy and cost savings, help companies evaluate the impact of their new systems.

- Adjusting Based on Data: Continuous monitoring and adjustments help ensure the company maximizes the return on its technology investment.

Prioritizing Security and Compliance

Security and regulatory compliance are vital when integrating new technologies. Protecting sensitive data and adhering to legal requirements maintain trust and minimize risks.

- Implementing Cybersecurity Measures: Companies should implement cybersecurity protocols like encryption and access controls to protect data.

- Ensuring Regulatory Compliance: Compliance with local and international regulations reduces legal risks and enables smooth operation across regions.

Conclusion

The NAPIPM 2018 event underscored the importance of resilient, technology-driven supply chains. By leveraging AI, blockchain, IoT, and automation, companies can build more adaptable, efficient supply chains. Implementing these technologies with best practices ensures a smoother transition and maximizes the return on investment.

FAQs

What technologies are most beneficial for supply chain resilience?

AI for forecasting, blockchain for transparency, and IoT for real-time monitoring are all critical for resilient supply chains.

How can companies start integrating new technologies into their supply chains?

Companies should begin by assessing needs, selecting compatible solutions, and providing adequate employee training and support.

What are the risks of adopting new supply chain technologies?

Some risks include cybersecurity vulnerabilities and potential compliance issues. Proper planning and security measures can mitigate these risks.

How do new technologies affect supplier relationships?

They improve communication and transparency, leading to better collaboration and more responsive partnerships.

How can companies ensure that technology investments are effective?

Companies should track KPIs, monitor impacts, and adjust strategies as needed to maximize technology benefits.